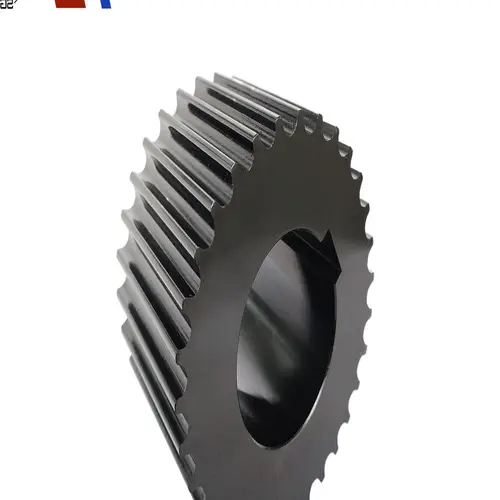

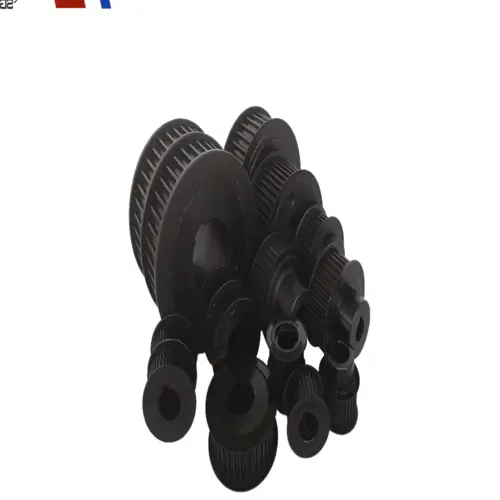

China Professional Factory Made HTD Timing Belt Pulley Aluminum Timing Pulley Air Compressor for Sale

Product Description

The HTD Timing Belt Pulley is a high-quality aluminum timing pulley designed for air compressors. It offers the following features:

- Teeth Profile: HTD, T&AT, STPD, RPP, PGGT (PowerGrip GT)

- Materials: Aluminum timing pulleys

- Characteristics:

- Suitable for moderate power transmission

- Lightweight with reduced rotational inertia

- Moderate chemical and corrosion resistance

- Standard material for stock pulleys

Steel timing pulleys are also available with the following characteristics:

- Suitable for high power transmission

- Durable

- Limited chemical and corrosion resistance

- Aesthetic material

Surface Finishes

Anodize Treatment (used on aluminum pulleys):

- Increased chemical and corrosion resistance

- Available in natural, black, or colored

- Limited increase of surface hardness

- Aesthetic treatment

Black Oxide (used on steel pulleys):

- Increased chemical and corrosion resistance

- Aesthetic treatment

Company Profile

Our company is a leading supplier of various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We strive to provide high-quality products, competitive prices, and excellent services. We welcome customization requests and offer prompt assistance to our customers.

FAQs

1. What are the teeth profiles available for the HTD Timing Belt Pulley?

The teeth profiles available for the HTD Timing Belt Pulley include HTD, T&AT, STPD, RPP, and PGGT (PowerGrip GT).

2. What materials are used for the aluminum timing pulleys?

The aluminum timing pulleys are made of high-quality aluminum material, which offers lightweight construction, reduced rotational inertia, and moderate chemical and corrosion resistance.

3. What are the advantages of using steel timing pulleys?

Steel timing pulleys are suitable for high power transmission and offer durability. However, they have limited chemical and corrosion resistance and are primarily chosen for aesthetic purposes.

4. What surface finishes are available for the pulleys?

The aluminum pulleys can be treated with anodize treatment, which provides increased chemical and corrosion resistance. The treatment is available in natural, black, or colored options. The steel pulleys can be treated with black oxide, offering increased chemical and corrosion resistance.

5. What other products does your company supply?

In addition to timing pulleys, our company supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products, competitive prices, and excellent customer service. We also provide customization options based on drawings and samples.

All content on this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to purchase original spare parts, please contact the original factory or supplier.

Performance Characteristics of HTD Pulley

HTD pulleys, also known as High Torque Drive pulleys, have a number of performance characteristics that make them ideal for a wide range of applications. Firstly, they have a high power transmission capability due to their tooth profile. They also have a low backlash, which means they are suited for applications that require high precision. In addition, they have a low noise level and smooth operation, which makes them perfect for use in areas where noise pollution is a concern. Finally, they have a long service life, making them a cost-effective solution for businesses.

Types and Characteristics of HTD Pulley

HTD pulleys come in two main types: Pilot Bore or Taper Bore. Pilot Bore pulleys have a fixed diameter bore, whereas Taper Bore pulleys have a tapered bore that allows them to be easily mounted onto a shaft. HTD pulleys can be made from a variety of materials, including Cast Iron, Steel, Aluminium, and Plastic. Each material has its own set of characteristics that make it suitable for different applications. For example, Cast Iron pulleys are known for their high strength, while Plastic pulleys are lightweight and resistant to chemical corrosion.

Advantages of HTD Pulley Made of Different Materials

Cast Iron HTD pulleys are the most commonly used due to their high strength and durability. They are ideal for use in heavy-duty applications, such as in manufacturing and printing. Steel HTD pulleys are also strong and durable, but are lighter than Cast Iron pulleys. They are often used in automotive and textile machinery. Aluminium HTD pulleys are lightweight and corrosion resistant, making them ideal for use in the aerospace industry. Plastic HTD pulleys are ideal for use in applications where chemical corrosion is a concern.

Application of HTD Pulley in Different Industries

HTD pulleys have a wide range of applications in various industries. In the manufacturing industry, they are used in conveyor belts and machinery. In the printing industry, they are used in printing presses. In the automotive industry, they are used in engines and transmissions. In the textile industry, they are used in weaving machines. In the aerospace industry, they are used in aircraft engines and landing gear. The versatility of HTD pulleys makes them a valuable component in many different fields.

Future Development Trends and Opportunities of HTD Pulley Products

The future of HTD pulley products looks bright, with growth opportunities in a number of areas. One trend is the increasing demand for lightweight and corrosion-resistant materials, such as Aluminium and Plastic. Another trend is the development of new tooth profiles that can improve efficiency and reduce noise. In addition, the growth of automation and robotics is creating new opportunities for HTD pulleys in industries such as logistics and packaging.

How to Choose a Suitable HTD Pulley

When choosing a suitable HTD pulley, there are several factors to consider. Firstly, the Load Capacity of the pulley must be taken into account to ensure it can handle the required load. Secondly, the Material of the pulley should be chosen based on the specific application requirements. Thirdly, the Diameter and Size of the pulley should be chosen based on the size of the application. Fourthly, the Type of pulley should be chosen based on the mounting requirements. Finally, the Bore Size of the pulley should be chosen based on the size of the shaft.

Conclusion

In conclusion, HTD pulleys are a versatile and cost-effective solution for a wide range of applications. Their performance characteristics, types, and materials make them suitable for many different industries, and their future development trends and opportunities are promising. When choosing a suitable HTD pulley, it is important to consider factors such as Load Capacity, Material, Diameter and Size, Type of pulley, and Bore Size. By carefully selecting the right HTD pulley for the job, businesses can improve their efficiency and reduce costs.

Author: Dream